Trajan is a global provider of engineered components and analytical technologies with a strong background in chromatography and mass spectrometry. These technologies enable measurements in biology, food and the environment.

We are a key partner in producing critical components and materials for analytical workflow and measurement. Our aim is to design and deliver a portfolio of analytical tools to enable best practice laboratory performance, enhancing confidence in result quality.

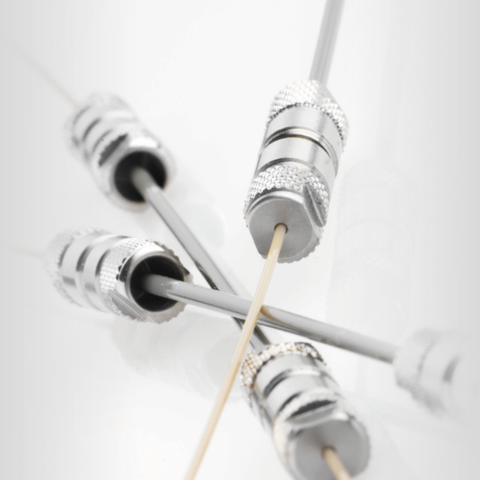

Analytical syringes

Separation science

Sample preparation